Yoder Lumber was featured in Holmes Edition of The Bargain Hunter in their July 7, 2014 issue:

When it comes to lumber yards, the wood rolls in, the wood rolls out and millions of board feet are produced on a regular basis.

Here in the heart of Amish Country, with countless wood builders grinding out everything from handcrafted furniture to flooring and molding and all kinds of wood-related products, the timber process is a necessity.

But how do timber yards evaluate their timber, provide a price and figure out their yields and the timber grade that is fair to both the customer and themselves?

That is the big question, and recently, a forestry grading staff from West Virginia University visited yoder Lumber to help them better understand the timber grading process. On Wednesday, June 25, the WVU staff met with yoder Lumber officials and witnessed the timber harvesting process, evaluating the grade of the lumber, the techniques being used and the efficiency of the company’s sawmill, to provide invaluable information that will aid Yoder Lumber in its ongoing efforts to improve and evolve.

As the logs rolled through the sawing process, the WVU staff watched as the Yoder Lumber crew worked diligently sawing up 100 preselected logs.

According to Trent Yoder, Yoder Lumber location manager at the Lake Buckhorn yard, their location manager in West Virginia, Gene Walters, who is a WVU graduate, knew of the grading program and highly urged Yoder Lumber to take advantage of it.

"We are basically taking a log, breaking it down and finding out what we get out of it," said Yoder, as they watched log after log being sawn into boards as the WVU staff prepared notes and took statistics.

"We can then come back and make sure we are cutting the logs we need to cut, and how to better grade them. That can help forecast our sales, and that better helps us meet the needs of our clients."

WVU has been providing this valuable research to companies for close to 12 years, and is one of very few universities in the nation to do so.

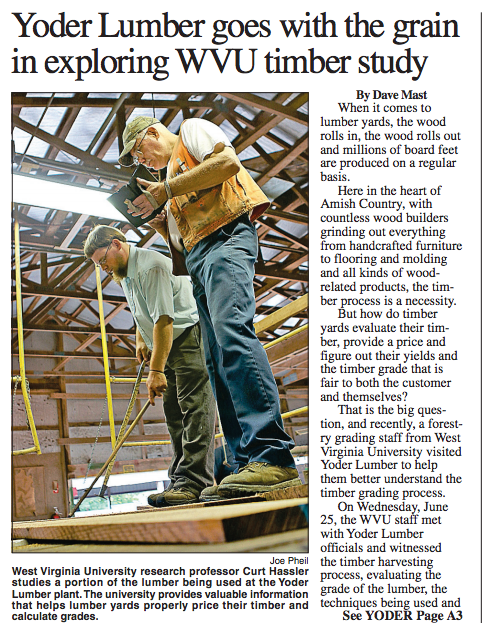

However, according to Curt Hassler, research professor at WVU, who along with research associate Larry Osborn was operating the research effort at Yoder Lumber, the university has really dug in and taken the program much more seriously since 2005.

WVU now does numerous studies throughout West Virginia, Ohio, North Carolina, Maryland, Pennsylvania and Virginia.

The two men took detailed notes during the entire process, and will compile a collection of data, which should be quite valuable for Yoder Lumber.

"Our biggest goal is simply to provide com pany’s with a better feel for their lumber grade yields, and their overrun and under run with their logs," said Hassler. "It provides them better information to price logs, which eventually be better for the retailers who purchase from them."

The study began one week prior to their grading June 25. The WVU staff works up all of the log data beforehand, selecting 100 logs of varying grades and quality.

Each log was carefully marked, observing diameter, length, condition of the timber and other crucial data.

Each log was marked on the end with a specific number, and then on the 25th, the logs were taken to Yoder Lumber, where the staff there did their thing, sawing each log into boards.

Each board is also marked, providing the WVU staff with volume and grade information. In addition, they time the process, which further helps them determine the cost efficiency of the lumber yard.

The information gathered by the university is processed, and within a week or two, is presented to the lumber yard.

Hassler said that through the multiple studies they have done, lumber yards use the information in a variety of ways.

"We have done this for a number of companies, and they have actually changed the way they have done business," said Hassler. "Many of the lumber mills we work with really don't know exactly what their lumber grade yield is. Sometimes this can be a real eye-opener."

Mel Yoder, Yoder Lumber CEO, said that regardless of the efficiency at which his company operates, finding ways to become even more efficient and cost-wise is an important part of creating better business.

"This is important because it shows us exactly what value we have in our logs we bring in," said Yoder. "It should help strengthen us economically. We have done some tests before, but never this thoroughly, we hope to improve on that, and by improving our efficiency and quality here in the plant, we can make sure we are profitable while passing along that savings and quality to our customers."

Bob Mapes, Yoder Lumber president, said that they felt fortunate to have the WVU staff provide such crucial insight into their operation.

"I think there are only two schools out there, WVU and Virginia Tech, who do this," said Mapes.

"We were very lucky to have them come up and do this for us. It is about creating more efficiency in our operations."

From locating a series of lumber on location, to harvesting, getting it into the mill and processed to finished product is not easy or cheap. But in gleaning the information provided, Yoder Lumber has taken important steps in streamlining their role in helping to create molding, flooring, furniture and the wide array of products requiring wood commodities

Click here to view the entire article in .PDF format.

Credit: