By: Norwegian Institute of Wood

Note: this article has been translated into English from the original Norwegian article

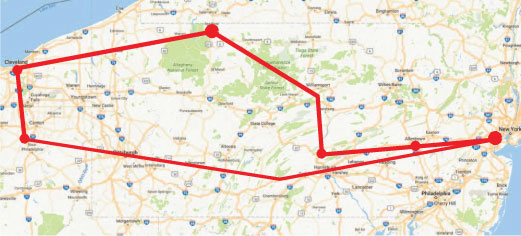

What do they do in America? 20 participants went in September to New York, Ohio and Pennsylvania, and had a very informative excursion. When Norwegians working in the wood industry travel abroad, they realize that here at home, they are highly equipped with technical equipment. It is also a lesson. The companies must have professionals who understand the wood industry and extremely modern technology.

There is a difference between refining the softwood of relatively homogeneous size and quality to broad-leaf with several variables.

Overall impression:

-

Rapid pace of work.

-

Small protective equipment and no corporate attire.

-

Not as automated as one would think.

-

Good products with fine finish.

-

Weak interest in forestry.

Eagle Machinery & Supply

The company Eagle Machinery & Supply is 15 years old and has 55 employees. They take care of the production of equipment for scanning, optimization, cutting, sharing, jointing, transport and planing mill solutions. The company is located in Sugarcreek, and has the whole world as its market. They have good sales on the West Coast, Asia, Australia, New Zealand etc. They create mechanical equipment and purchase scanning through Woodeye in Sweden. The programming takes place in the company, while the assembly is undertaken and carried out at the customer.

The equipment was characterized by very solid dimensions and good finish. To establish a good delivery, all devices were tested in the company for the first time. Before scanning, customers had 1 to 2 weeks of training. The purpose is to get a quick payback. Softwoods are quite easy to sort, while hardwood contains much more irregularities. This aspect is often necessary to follow up. The Norwegian Sawmill Industries Association got a very solid presentation emphasizing that a good planning and training were the key to a good delivery. It is considered to be very important to monitor the company after the delivery and ensure that they have the satisfactory expertise and utilize the equipment in the best possible way.

The group was presented to companies in the immediate area, Yoder and Keim, where they have delivered pretty much. The Americans are very hospitable and we got a good introduction to living there in the ancient times and now.

Yoder Lumber, Buckhorn Sawmill

Rough timber of appalachian hardwoods is mostly cut in here. The timber is sprinkled. Debarking is undertaken by 2 mills. It’s almost like a machine that removes the root and other irregularities of the log.

A slanted vertical band saw cuts down a block that is passed over a cutting saw. The side boards are then transferred to an optimizer and edger. On the raw sorting, there is an inclined disc that applies wax to the end of the board to reduce cracks during drying. The timber has a humidity of about 50% before being stored in the shed, and is dried down to 6 - 8%. The market is local, but China buys much rough dimensions.

Yoder Lumber, Berlin Dimension Mill

Mainly red oak and poplar are undergoing planing and are bonded here. At this plant over 50 employees work 9 hours, 4 days a week and half a day on Friday. Due to the varying raw material, it is crucial to get a good real yield. Laser light was used on the wide board to align. The scanning and automate cutting increased the yield by 5%.

Learn More at the Institute of Norwegian Wood